Autophoresi Chemical Coating

ZINCO-CROMATURA srl installed the first Autophoresi

ACC® 866 plant in Italy in December 2000 on licence from

HST.

With this new technology, patented by HST, you

obtain ionic self-separating plating on metal and composite surfaces

that are highly elastic and resistant to corrosion.

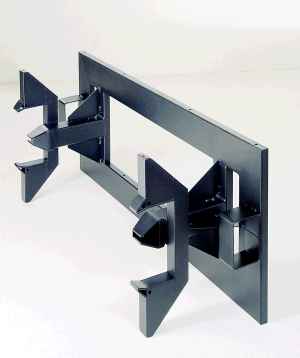

Autophoresi is a coating that can also be applied on surfaces that

are hard to reach with the usual plating systems.

The

plating is based on the CHEMICAL REACTION between the reactive bath

and the ferrous surfaces immerged in the same that are covered

uniformly regardless of their shape.

This treatment

has the properties of guaranteeing protection on parts with

cavities, protuberances and straight or shaped pipes, in which case

the protection is also applied inside the same as well as outside.

Plastic or rubber parts aren't coated so it is

possible to treat objects that have already been assembled with

these materials, considering that the highest temperatures of the

process don't exceed 100/120°C.

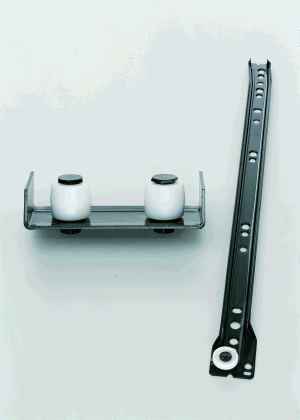

Threaded nuts and

bolts can be treated normally because Autophoresi doesn't leave

deposits on the threads, but respects their conformity.

For the car industry, this treatment has integrated

the traditional rust-prevention system and also in this sector,

Autophoresi can be used on parts with complex shapes.

The Autophoretic treatment is an

ECOLOGICAL process.

The parts

treated with the Autophoresi ACC® 866 process are treated

without:

Parts treated with Autophoresi are at the end of the

productive process, ready for packing and therefore it is possible

to avoid having semi-finished parts sitting in the warehouse and

also simplify bureaucratic procedures and costly warehouse

management.

This gives you an idea of the enormous

economic advantages that the client has by choosing the Autophoretic

coating for their articles.

|